Catalog

-

Catalog

- Agriculture

- Apparel

- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery, Hardware & Tools

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Filters

Search

copper mould tube

original price: 500,00 USD

Jiaxing, China

Production capacity:

50000 Set / Year

Jay Huang

Contact person

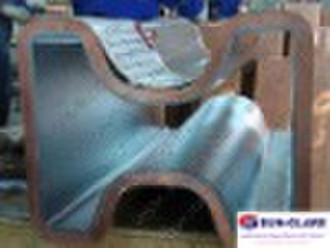

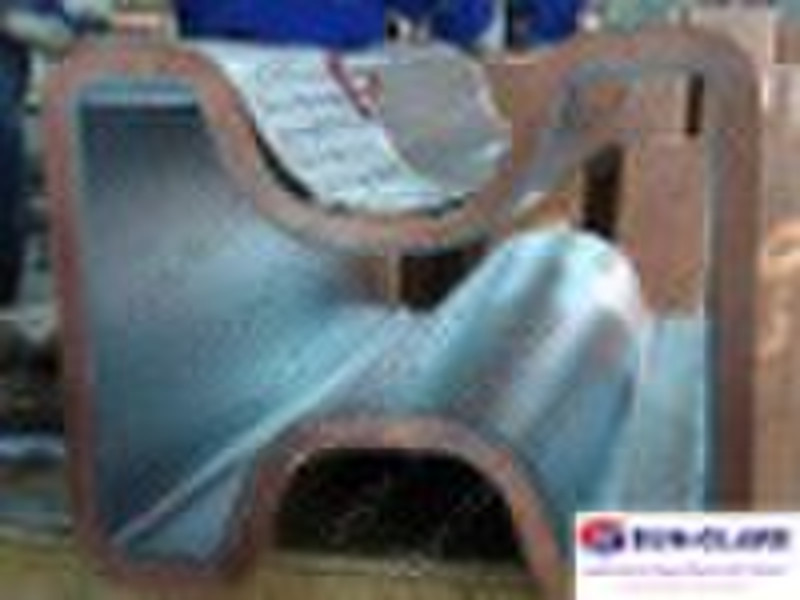

Basic Information

Specifications of Sun-Glare copper mould: Design: Square, rectangular, round, plat, H-beem Straight or curved Outer contour parallel Internal geometries: parallel, single tapered, double tapered, multi tapered, parabolic tapered Size: Square: 90 320mm; rectangular: max.310X410mm, round: 800mm Length: up to 1200mm Wall thickness: up to 32mm Curved radius: 3000 12000mm Larger size on special inquiry plate: 4000X1200mm Coating: Chrome coating with thickness of 0.06 0.13mm Besides mould supply, we design and manufacture water jacket and mould assembly tailored to your caster. 1.melting/casting(material): development of continuous casting technology demands more on material and design of cooper mould tube.working under serious high-temperature condition,the material must have basic features such as good thermal conductivity,high strength,wear-resistance,suffcient hardness and high re-crystallization temperature ect. according to different working condition,Sun-Glare provides suitable choice of mould materials. material material content(%) mechanical performance Conductivity (%IACS) Cu others Tensile strength σb (N/mm2) Yield strength σ0.2 (N/mm2) Elongation δ (%) hardness HB ≥ E-Cu 99.9 0.01 200 40 40 45 98 SF-Cu (DHP Cu) 99.85 P0.12 305 235 18 85 85 CuAg 99.9 Ag0.07-0.12 250 200 10 80 98 Cu-Cr-Zr 98.0 Cr0.5-1.5 Zr0.08-0.3 350 280 10 110 70 2.hot drawing 3.cold drawing 4.test after maching 5.plating after cleaning 6. quality control after pickling

Delivery terms and packaging

Packaging Detail: ocean shipping Delivery Detail: 45days

Port: ShangHai

Payment term

Letter of credit

-

Payment Methods

We accept: